About PET Bristle Monofilament Extrusion Plant

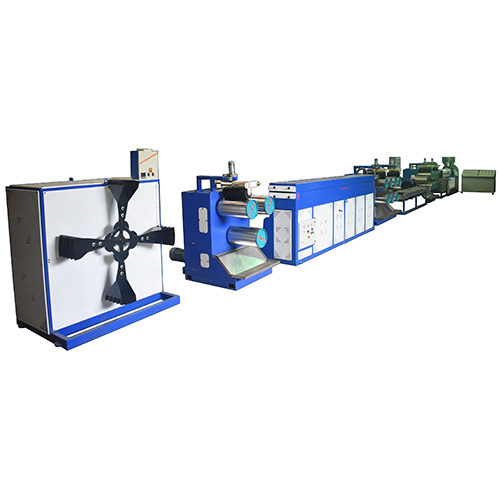

The PET Bristle Monofilament Extrusion Plant is a robust, high-performance solution for manufacturing PET and PP bristles used in a wide range of applications such as paint brushes, cleaning tools, home brooms, and fashion fabrics. Made in India, this versatile extrusion plant is available in manual, semi-automatic, and automatic configurations, ensuring adaptability to different operational requirements. With production capacities ranging from 700kg to 5 tons per day and a maximum line speed of 180MPM, it offers efficiency and scalability. Equipped with advanced models (SYN/BT-55/65/75/80/90/100/110), its performance depends on raw material, line speed, and screw diameter. Powered by motors ranging from 160Hp to 250Hp, the plant is designed for high precision and consistent output. This extrusion plant is ideal for businesses seeking reliable machinery to meet diverse manufacturing needs as both exporters and manufacturers.

FAQs of PET Bristle Monofilament Extrusion Plant:

Q: What types of plastics can be processed by this extrusion plant?

A: This extrusion plant can process both PET and PP materials effectively.

Q: What is the production capacity of the extrusion plant?

A: The production capacity ranges from 700kg to 5 tons per day, depending on the model and operational parameters.

Q: What operational configurations are offered for this plant?

A: The plant is available in manual, semi-automatic, and automatic configurations.

Q: What kind of applications can the bristle monofilament be used for?

A: The bristle monofilaments are used in paint brushes, cleaning tools, home brooms, fashion fabrics, and more.

Q: What is the maximum motor power of this extrusion plant?

A: The extrusion plant is powered by motors with a capacity of 160Hp to 250Hp, depending on the model.